Clinical Cases

Patient-specific surgical guides for femoral osteotomy

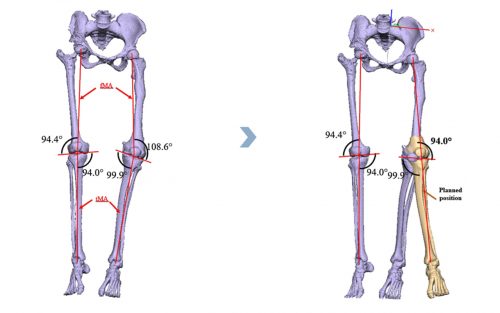

Polytraumatic injury has left a patient with severe consequences in lower extremities and pelvic bones. Additionally, left femoral malunion was found, causing alterations in knee joint, therefore, a risk emerged for further impairments to the ankle and hip joints, as well as to gait.

-

1st step

Patient underwent Computed Tomography (CT) scan. Surgeon initiated new case in MICE and uploaded patient‘s CT data.

-

2nd step

Surgeon simulated surgical actions on 3D anatomical models of patient‘s lower extremities – taking into account the automatically-calculated anthropometric parameters, surgeon virtually performed femoral osteotomy and positioned femoral segments to achieve restoration of leg according to anatomical and mechanical axes. Surgeon also specified preferred characteristics for the design of patient-specific surgical guide: resection height, fixation, geometrical characteristics, etc.

-

3rd step

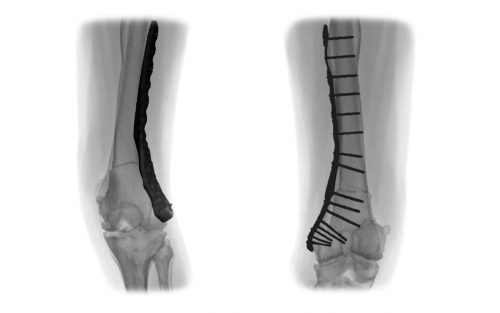

Taking into account provided specifications and anthropometric measurements, patient-specific surgical guide has been designed according to planned femoral osteotomy and final position of femoral segments. Surgeon validated the design of surgical guide and other features of device package

-

4th step

Patient-specific surgical guide was manufactured using additive manufacturing technology Selective Laser Sintering. Device underwent postprocessing and quality control tests. At the same time, accompanying documentation was prepared with detailed illustrations regarding surgery plan and positioning of the femoral segments.

-

5th step

3D-printed assembled anatomical models and patient-specific surgical guides assisted surgeons during surgery to fulfil pre-surgical plan by indicating resection lines and position femoral segments and standard osteosynthesis plate. Intrasurgical and postsurgical radiograms showed precise alignment of femoral segments; patient’s anatomical and mechanical axes of left leg were successfully restored

How can I be a part of fit2patient?

The fit2patient platform together with the MICE software system allows you to design patient specific implants on web-based platform using 3D models. What is more, the pre-surgical planning becomes an easier and more convenient process. Want to know how it is possible? Contact us and become our platform partners!

About us

We are Ortho Baltic, in market more known as producer of custom-made prosthetic-orthotic devices under the name of Ortho Baltic, in 2012 we have invested in additive manufacturing technologies and expanded our made-to-order services to the design and production of patient-specific joint endoprosthesis, cranial and maxillofacial implants, bone plating systems, dental & jaw restoration implants and patient-specific surgical guides as well.

Taikos Ave. 131A

LT-51124 Kaunas, Lithuania

Tel. 8 37 473970, Fax 8 37 473863

info@fit2patient.com