Clinical Cases

Patient-specific temporomandibular joint endoprosthesis for treatment of bilateral ankylosis

Patient complained of disturbed mandible movement, inability to open mouth fully, eat or do dental treatment. The symptoms appeared 7 years ago (i.e. 1 year after car accident where she suffered from mandibular fracture) and become worse over time.

Patient was found with maximal mouth opening (MIO) 2 mm, inability of lateral TMJ movement, rheumatoid arthritis; orthopantomogram showed bone conglomerates in both TMJs.

-

1st step

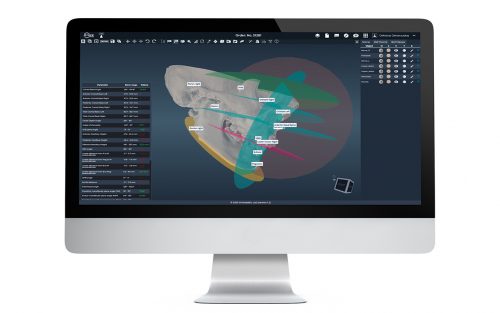

Patient underwent Computed Tomography (CT). Surgeon initiated new case in MICE and uploaded patient‘s CT data

-

2nd step

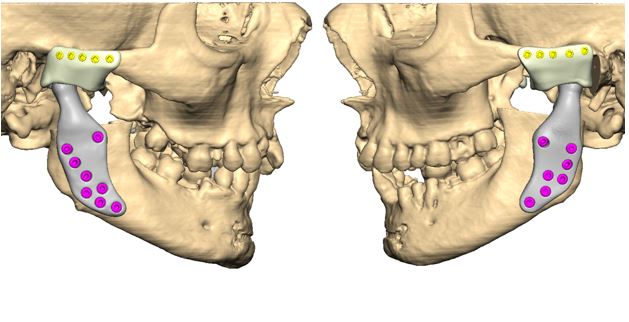

By simulating surgical actions on 3D anatomical models of patient‘s skull, surgeon takes into account the automatically-calculated cephalometric parameters, and specifies preferred characteristics for the design of patient-specific implants and surgical guides: resection height, fixation, geometrical characteristics, occlusion adjustments etc

-

3rd step

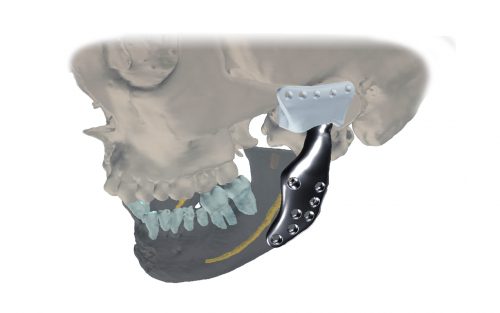

After taking into account provided specifications and cephalometric measurements, patient-specific implant and surgical guides have been designed. Furthermore, mandible position correction was planned for restoring facial symmetry and proper occlusion. Surgeon validates the design of endoprosthesis components and surgical guides, as well as other features of device package

-

4th step

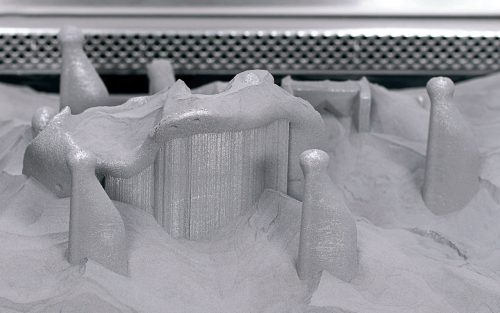

Patient-specific endoprosthesis components and surgical guides have been manufactured using 3D printing and milling technologies; Each component underwent quality control analyses of the geometry, surface roughness, internal defects and chemical composition.

-

5th step

3D-printed assembled anatomical models and patient-specific surgical guides assisted surgeons during surgery to fulfil pre-surgical plan by indicating resection lines and position of patient-specific endoprosthesis components. Postsurgical radiograms showed precise component fit and position; patient mouth opening and occlusion were successfully restored.

How can I be a part of fit2patient?

The fit2patient platform together with the MICE software system allows you to design patient specific implants on web-based platform using 3D models. What is more, the pre-surgical planning becomes an easier and more convenient process. Want to know how it is possible? Contact us and become our platform partners!

About us

We are Ortho Baltic, in market more known as producer of custom-made prosthetic-orthotic devices under the name of Ortho Baltic, in 2012 we have invested in additive manufacturing technologies and expanded our made-to-order services to the design and production of patient-specific joint endoprosthesis, cranial and maxillofacial implants, bone plating systems, dental & jaw restoration implants and patient-specific surgical guides as well.

Taikos Ave. 131A

LT-51124 Kaunas, Lithuania

Tel. 8 37 473970, Fax 8 37 473863

info@fit2patient.com